Photovoltaics

Mounting systems

Pitched roof | Flat roof |

ground mounting | Carports | individual solutions

Freifläche

Unser Freiland Montagesystem SILENOS zeichnet sich durch seinen einfachen Aufbau und seine flexiblen Einstell- und Ausgleichsmöglichkeiten aus.

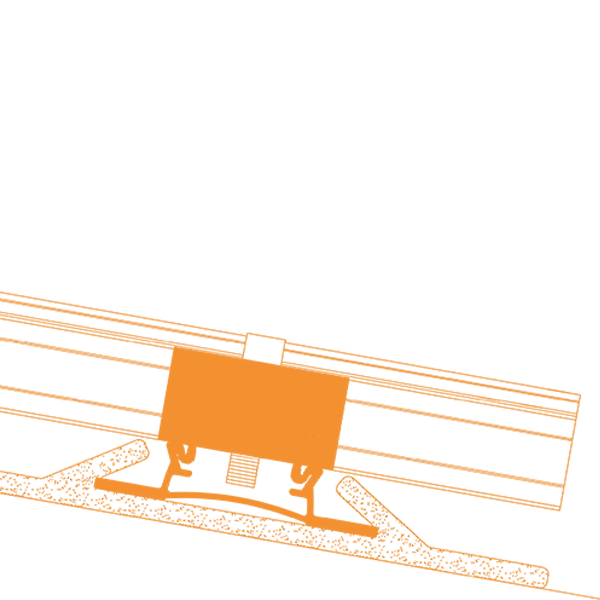

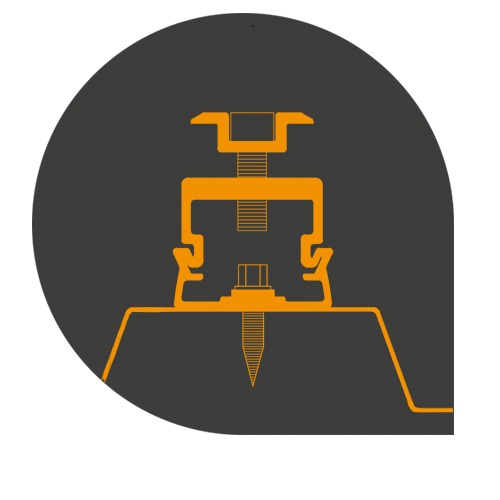

Flachdach

Unser vormontiertes, aerodynamisches TRITON-Flachdachmontagesystem garantiert eine Montage in Rekordzeit mit geringem Ballast.

Pitched roof

With our CHRONOS and ZELOS mounting systems, we have two solutions for pitched roofs. Especially for slightly sloped foil and bitumen roofs we used our aerodynamic METIS system.

Carport

Unser HELIOS Carport ist als Einzel-, Doppel- oder beliebig skalierbarer Reihencarport erhältlich. Ein großer Abstand zwischen den W-förmigen Stützen ermöglicht einfaches Parken.

T.Werk GmbH

PV mounting systems

We develop the appropriate substructure for almost all roofs and open spaces. Quick and easy assembly is a top priority for our development department.

We are an ISO 9001:2015 certified company and support you in the planning as well as design of your PV system and are happy to advise you in various matters.

Our services:

12 years warranty for all mounting systems | Our warranty conditions

Individual assembly solutions

With us you can choose from a wide range of products. Open spaces, landfills, foil roofs, green roofs, trapezoidal roofs, tile roofs, seam roofs, facade… We have a solution for everything. If something doesn’t fit, it will be made to fit.

Quick assembly

Our mounting systems are child’s play to assemble and require virtually no training time. With our products, you become more efficient on the construction site and can use your capacities wisely. Because time is their most precious commodity.

High quality, safe & inexpensive

Support in any matter

We not only provide you with sophisticated assembly systems, but also with services tailored to your individual needs so that you can concentrate on your core processes. This is where we contribute our many years of experience and our professional network.

Quality & Effectiveness

12 years product warranty

Frequently asked questions.

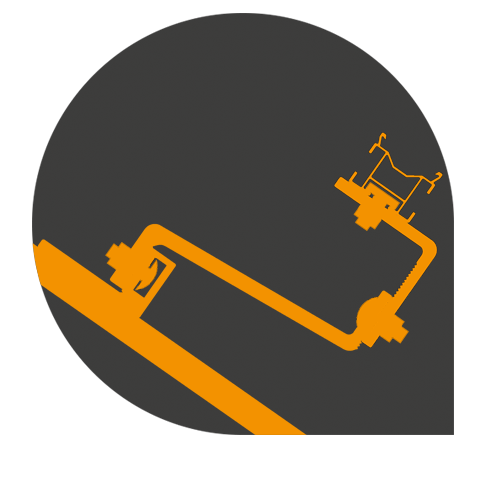

Is the TRITON flat roof system firmly connected to the roof?

No, the Triton system for flat roofs is installed without a fixed connection to the roof. This prevents unnecessary damage to the roof cladding and thus eliminates a potential source of danger, such as unintentional water penetration into the building. Lifting and slipping of the module field is counteracted by ballasting the mounting system. The necessary calculation basis for this is provided by wind tunnel tests of the Triton flat roof mounting system by the IFI Institute in Aachen.

Does the east/west orientation or the south orientation of the mounting system make more sense?

We realize the alignment of the Triton flat roof mounting system on customer request depending on the project. In order to mount the highest possible output of solar modules on the available roof area, the Triton East/West elevation with 12° inclination is predestined. The maximum yield per installed module area is achieved with the Triton South elevation (available in 10°, 12° and 15°).

How far apart are the module rows?

The spacing of the module rows depends on the angle of incidence of the sun at the respective project location. In order to prevent mutual shading of the module rows, the module that is installed during the lowest position of the sun on 12/21. required distance calculated. If the power per available roof area is to be increased by smaller distances between the module rows, partial shading is recommended in the period from 15.11.. until 27.01. received.

What is the assembly time for the mounting system?

We guarantee very fast assembly times for each of our assembly systems. We achieve this through a simple and easy-to-understand design of the systems and a high degree of pre-assembly. In doing so, we achieve assembly times that are up to 50% shorter than comparable assembly systems.

How long has T.Werk been on the market and what experience does T.Werk have?

T.Werk GmbH was founded in 2012. The co-founder and managing director Markus Ziegler could already draw on more than 5 years of experience as technical manager of a substructure manufacturer. T.Werk has sold several hundred MWp of substructure to date and has installed over 60 international ground-mounted projects, for example.

In which countries is T.Werk active?

T.Werk assembly systems are already used worldwide. However, the main sales market is the German market. All projects are currently coordinated and supplied from the company headquarters in Burgau.

Is T.Werk the manufacturer of its mounting systems?

Yes, T.Werk is manufacturer. We develop and design our products with our engineers. Here we are always in lively exchange with our customers and fitters.

What information is needed for me to get a quote?

To make an inquiry, please fill out our data entry form and preferably send us a module assignment plan. The most important information, in addition to the module used, is the location, technical details of the roof and the desired method of installation.

Can modules with special dimensions also be installed with the T.Werk mounting system?

Yes, almost all modules can be installed. In addition to the standard 60 cell modules, 72 cell modules, frameless glass-glass laminates, the “old” monocrystalline modules (1580 x 808 mm) as well as hybrid modules and hot water collectors can also be installed.

Introduction Team T.Werk

We give you an insight into the T.Werk. team. Manuel Lindenmayer answers five questions about his experiences with us. What is your role at T.Werk and how long have you been there? My job is the project planning and design of mounting systems for solar installations...

T.Werk has moved – new address

We have moved! We are looking forward to continuing our journey in a new place. We have been at our new location in Burgau for a few weeks now. Toasters and kettles were produced here on the site of the former Petra-Electric company until the end of August 2011. We...

Company vacation Christmas 2023

???? Important information for our T.Werk partners! ???? We would like to inform you that we are going on vacation. The last shipping day before our break is December 15. Our company vacation begins on December 22, 2023 and lasts up to and including January 5, 2024....